Drop siding that could finish a wall without sheathing was ideal for temperate climates, making it a favorite for the ubiquitous bungalows of the 20th century. (Photo: Gordon Bock)

Illustrations by Rob Leanna

Wood, at one time or another, has been used to make every part of old houses, from foundations and structural framing to roofing and wall cladding. The first settlers that landed in North America brought with them the methods for covering roofs and walls with wood shingles split from short lengths of logs, however, it was the rich supply of tall, straight trees they found here that gave rise to a new and different kind of wood building material: horizontal siding.

The clapboard and its variants are the original horizontal siding, dating back to the earliest, hand-rived types from the 17th century, but they are only the progenitors of a family of materials that took off with the Industrial Revolution. With the widespread use of steam-powered millwork machinery in the 1850s, horizontal siding proliferated into patterns of striking creativity, to satisfy the Victorian taste for texture, or simply efficiency—such as ersatz versions of log façades or even the venerable clapboard. By the 1930s, standard millwork references listed no less than 28 different types of commonly available horizontal siding. Since many are no longer familiar today and are difficult to purchase (especially at one-size-fits-all home centers), we have put together this glossary of the basic types and how they are installed, for use by anyone who has to repair or alter a horizontally sided old house built in the last 150 years.

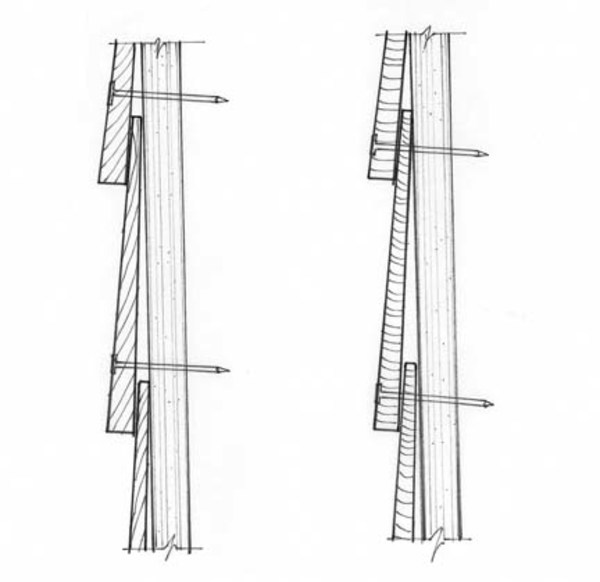

Clapboard & Beveled Siding

Clapboard is plain, beveled siding, a near-isosceles triangle when viewed on-end. Traditional New England clapboard is cut radially from the log (producing true vertical grain) and up to 6” wide. Bevel siding and bungalow siding are 20th-century versions that are generally resawn from boards (producing random grain) to obtain widths of 8” and more. Manufacturers recommend nailing modern resawn bevel siding through a single board to allow for wood movement (at left). Traditional clapboard with true vertical grain is typically nailed through both boards to sheathing (at right).

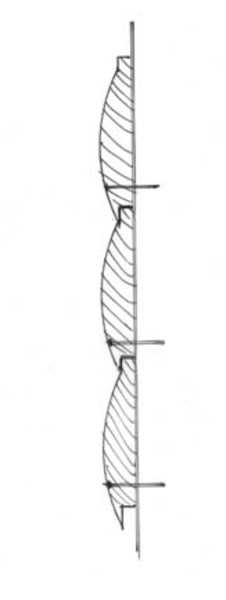

Novelty Siding

A term that is also applied to all patterns of drop siding—milled siding that lies flat on the wall surface—novelty is frequently associated with the ubiquitous cove pattern also called German siding in some areas. Popular by the 1880s, and possibly in use as early as 1860, it is typically edge-matched in a shiplap joint, but was also produced in tongue-and-groove. Novelty siding that swaps a bevel for the cove is often called channel rustic. Tongue-and-groove novelty types may be blind-nailed at the tongue (at left). Cove-style novelty siding is typically face-nailed, sometimes directly to studs in light-weather areas or buildings (at right).

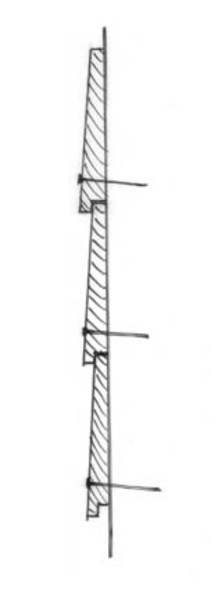

Rustic Siding

Rustic siding is a broad term often applied to several types of siding milled to present an appearance much more like timber than their actual thickness. The classic example is log cabin siding—a peeled log simulation with shiplapped joints. Log cabin siding was common by the 1930s, in 6,” 8,” and 10” widths. Log cabin siding is typically face-nailed above the rabbet edge with a single nail, though wide patterns may require nails on both edges.

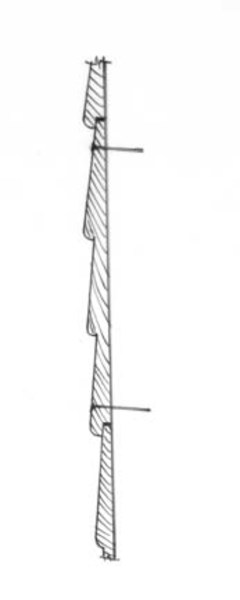

Double Ogee Siding

Representative of an extensive subset of drop siding types, double ogee is a single siding board milled to present the shadow lines of two boards. The concept was applied to many other patterns (the double coves of novelty siding, double bevels, etc.) and, in some areas was even extended to triple ogee siding. These products were usually shiplapped, but also appeared in tongue-and-groove versions. Double ogee was common by 1910. Double ogee is typically face-nailed above the rabbet edge with a single nail, though wide patterns may require nails on both edges.

Dolly Varden Siding

Sometimes considered rustic siding, especially when milled with an unplanned face, Dolly Varden is a bevel siding simulation made with a rabbeted bottom edge, so that the siding installs flat on the wall with a tight joint. It dates to at least the 1930s. Dolly Varden is typically face-nailed above the rabbet edge with a single nail, though wide patterns may require nails on both edges.