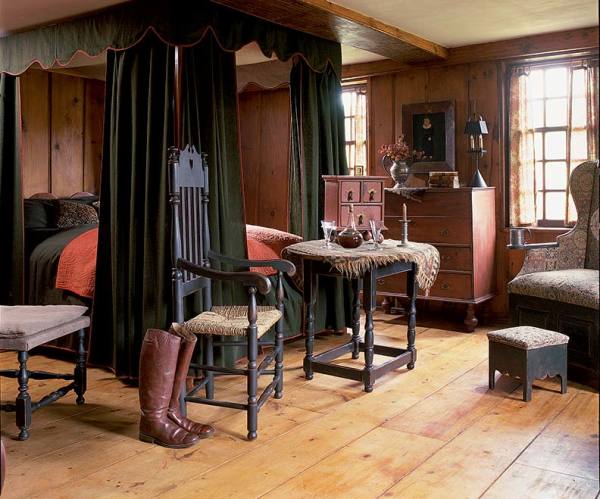

On new wide-plank pine boards in a ca. 1700 house, the edges were beveled down to make the floor look old. (Photo: Gross & Daley)

Q: What are some of the key characteristics of old wood flooring?

Early wood floors tended to be wide, with planks averaging between 6″ and 12″ or more. The widest boards (up to 24″) were used to sheath broad surfaces because they required fewer joints and fasteners, says Mark Thibeau of Craftsman Lumber. They were sometimes up to 16′ long. These magnificent floors were harvested from old-growth trees whose tight, dense grain gave the wood a longevity that woods harvested today can’t match.

In the Northeast, wood species include Eastern white pine, “hard” red and yellow pine, poplar, oak, and chestnut. “Hard” pines, which mellow to a color often called pumpkin pine, are especially prevalent in New England. In the South, longleaf pine— source of the most desirable heart pine flooring—was harvested later and is pervasive from eastern Virginia to Texas.

Q: How was the wood cut and laid?

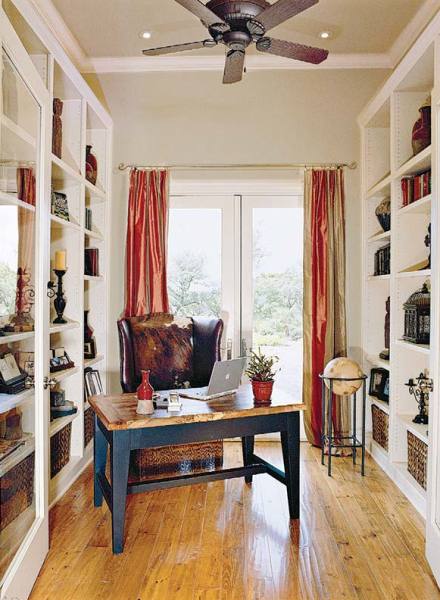

A heart pine floor from Goodwin includes boards with the repeating “cathedral” grain characteristic of plain-sawn wood.

Wood was either plain-sawn or quarter-sawn. Plain-sawn heart pine produces a repeating pattern of what are called “cathedral arches,” says Jeffrey Forbes of the Goodwin Company. “They’re a repeating pattern of arching grain, layered one on top of the other along the board.” Quarter-sawn wood produces boards with a vertical grain, like pin-striping, Forbes says. In some houses with plain-sawn floors, “you will find vertical grain on the edges of some of the wider boards.” That’s because the board was cut to the full width of the log.

The earliest boards were random-width planks laid tightly against one another with square edges, and either face or blind nailed. (Truly early floors were fastened to underlying joists with pegs.) Boards also could be cut with interlocking tongue-and-groove joints, then blind nailed. Other characteristics of old flooring include uneven wear from years of use and knotholes, depending on the type of wood.

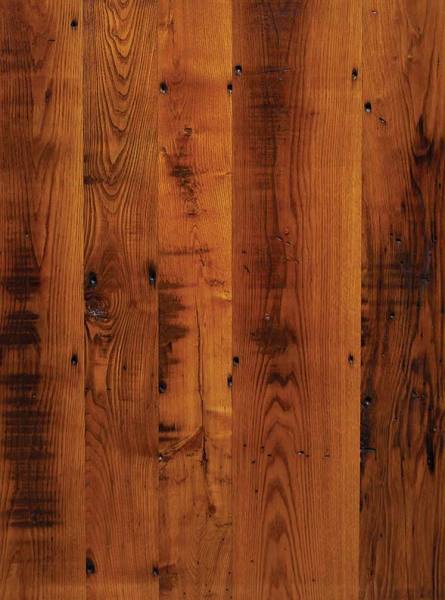

Floorboards reclaimed from an attic with their original finish, Sylvan Brandt.

Q: Is wood like this still available today?

Some woods, like chestnut, are “commercially extinct” because there are no viable trees left. But many types of woods used historically—including chestnut—can be reclaimed from industrial buildings, attics, and barns, or recovered from the bottoms of lakes and rivers. Sustainably harvested new wood is still available in widths and lengths seen in colonial times. For example, Craftsman Lumber’s wide pine boards average 6″ to 22″ wide, with an occasional board up to 28″. Lengths range up to 16′.

Reclaimed wood is often as old and full of character as the floors in a house two centuries old, or perhaps more. “Saw marks were original on early floors, but they wore off when people walked on them,” says Dean Brandt of Sylvan Brandt. “That’s why attic boards are so valuable. They haven’t been walked on, and they have no polish or polyurethane on them.” Similarly, the protected side of old barn wood has an aged patina and untouched saw marks.

A hand-scraped Southern longleaf pine floor from <a href="

Longleaf pine pulled from lakes and rivers is equally old, says Forbes. Because it’s been underwater so long, the wood is highly resinous and rich in patina—skewing toward the golden or yellow end of the spectrum as opposed to similar wood that’s been exposed to air for more than a century. Heart pine is photo-reactive, which means that “if you marry newly cut river-recovered boards with an old floor, the new boards will darken into a harmony with it.” The grain also will be a close match.

Q: How are woods priced, and what are some options for more affordable flooring?

Heart pine in random widths and lengths starts at $5 or $6 per square foot, says the Goodwin Company’s Forbes. Boards that average 6″ or 7″ in width can sell for $20 to $25 per square foot. At Sylvan Brandt, most woods cost between $7 and $13 per square foot. The range at Craftsman Lumber starts at about $4 for new white pine and ranges up to $20 per square foot for reclaimed chestnut. At about $4.50 per square foot, Thibeau considers new wide-board white pine flooring a bargain. “You’re going to pay half the money you’d pay for reclaimed.”

Reclaimed chestnut skip-planed for character from <a href="

Another cost-saving option is engineered heart-pine flooring, which costs about $5 per square foot from Goodwin, a pioneer in the technology. The dimensionally stable wood installs easily and has a solid wood top layer that’s “a fat 1/8″ thick,” Forbes says. “You could sand it two or three times in its lifetime.”

Sylvan Brandt sometimes has lots of shorter boards on hand that still offer good quality, says the company’s Genna Antes. “We’ll sell shorts at a discounted price when we have them.” At $7 per square foot, she sees narrow-board resawn oak flooring as a good value compared to some engineered floors. “By the time you get into a hand-scraped product where they’re trying to make it look old, you’re at the same price.”

For more sources, see the Products & Services Directory.