Bryan Byrd, started the company in 2001

When American Restoration Tile founder Bryan Byrd died suddenly five years ago, his two daughters were faced with a choice: let the family business go, or run it themselves. Erin Byrd Oliver and Rachel Byrd Silvestri chose to keep it going. “We thought we owed it to the employees to at least give their jobs a chance,” says Oliver, who deals with clients and sales while Silvestri runs production and human resources, and finesses the trickier designs. The company is in Mabelvale, Arkansas.

Five years on, the sisters are more than happy with their decision. Business is booming, and the number of employees has doubled. “We’ve made about three times as much tile this year as Dad did in 2016,” Oliver says.

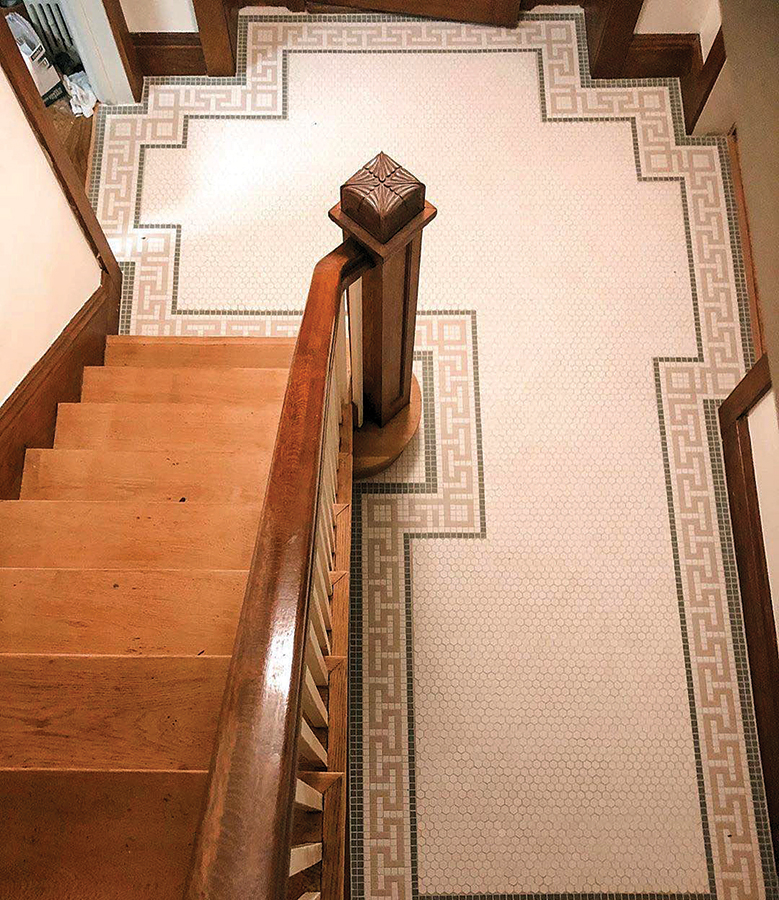

Colloquially known as ART, the company makes the small, flat tiles called mosaics. In specific shapes such square, hexagon, and penny round, the tiles lend themselves to a wide array of patterns (usually on a white ground), from stars and flowers to geometrics and intricate borders.

Like mosaic tile made between 1885 and 1945, all ART tile is unglazed, full-body porcelain, meaning the color runs straight through the tile from top to bottom. The tops are perfectly flat without bevels or cushions. Grout lines are thin—a hygienic response to the late-19th-century “sanitary” movement. Tiles are small, and ¼” thick without exception.

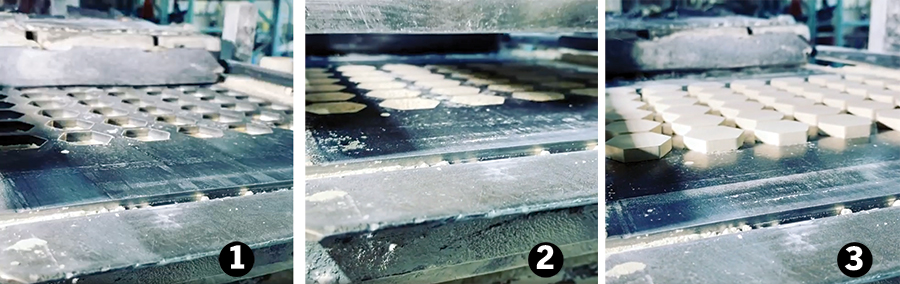

Both women say making tile is “a lot like making cookies.” Raw materials for each color are mixed dry in a large mixer, with just enough water added to make the clay pressable. The tiles are formed under pressure, then fired. One batch yields about 30 square feet of tile.

Step one : The die, the “cookie cutter” part of the tile-making operation, ready for a batch of dry mix.

Step two: With the dough in place, the hydraulic press bears down.

Step three: The press retreats, leaving crisp-edged hexagonal tiles ready for firing.

The small-batch process may be one reason there’s always a long lead time at ART. Affordable compared to hand-pressed art tiles, mosaic tiles are typically priced at $38 to $40 per sq. ft. About 75% is sold to owners of old houses, for new work and patching, with the rest going to new-builds and to commercial or institutional clients.

“Nine people touch each tile before it heads out the door,” Erin Oliver says. “It’s not that we’re doing anything magical. It’s that we take the time to do it right,” using traditional specifications.