Most roofing contractors work with asphalt or composite roofing. If they install metal, slate, or tile roofs, their ads and websites will stipulate those specialties. For extensive work or replacement of a wood-shingle roof or any of these long-lived roofing materials, hire a company with the right experience. A few old-fashioned repairs for minor problems are DIY-friendly, provided you are comfortable working on the roof and you follow all safety procedures.

How to Repair Wood Shingles

These may curl and split or become thin through long weathering. If the problem is just a random shingle here and there, replacement is a simple job. If the number of shingles needing replacement approaches 10 or 15%, though, think about replacing the entire roof.

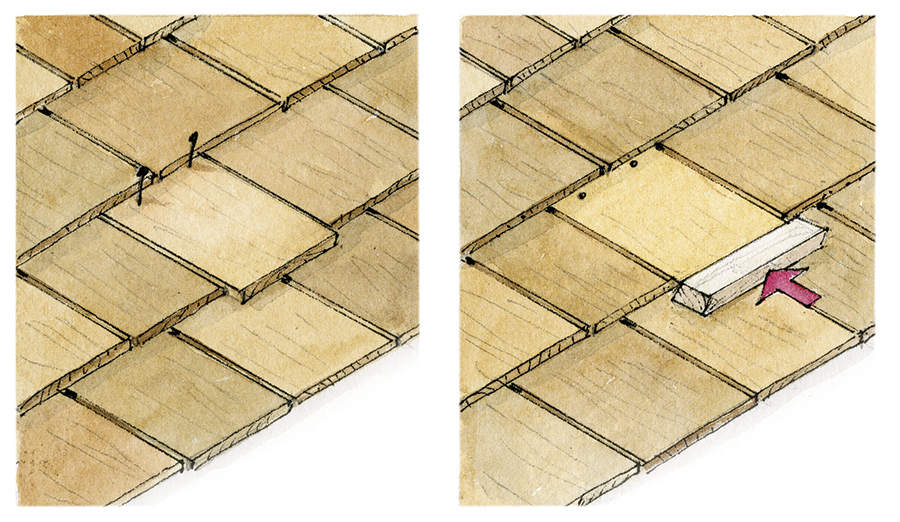

To replace a wood shingle, remove the damaged unit by splitting it into several smaller pieces with a chisel, until all parts come free of nails. Cut the heads off the nails, using a slate ripper or hacksaw blade inserted up under the shingles. The replacement shingle may be held with a copper tab or a toe-nailing technique.

A very temporary repair for a split shingle may be made by inserting a piece of sheet metal under the damaged area.

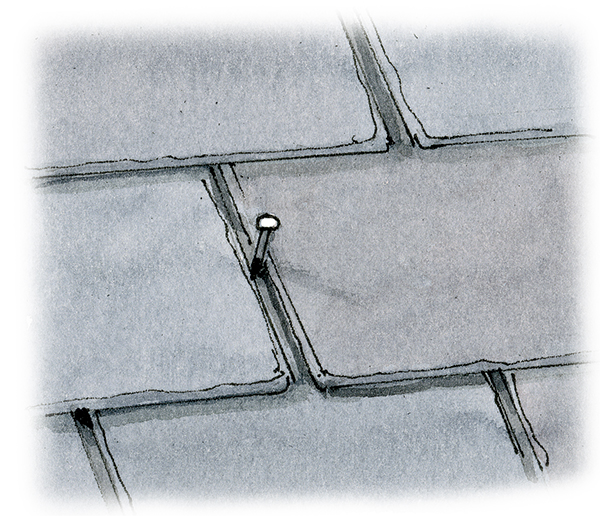

Left: After removing the damaged shingles, slip in a replacement, allowing it to protrude ¼” below other shingles in the course. Toe-nail two finish nails immediately below the course above. Right: With a hammer and a wooden block, strike the end of the new shingle, driving it up level with the others, thus bending the nails and putting the heads below upper shingles.

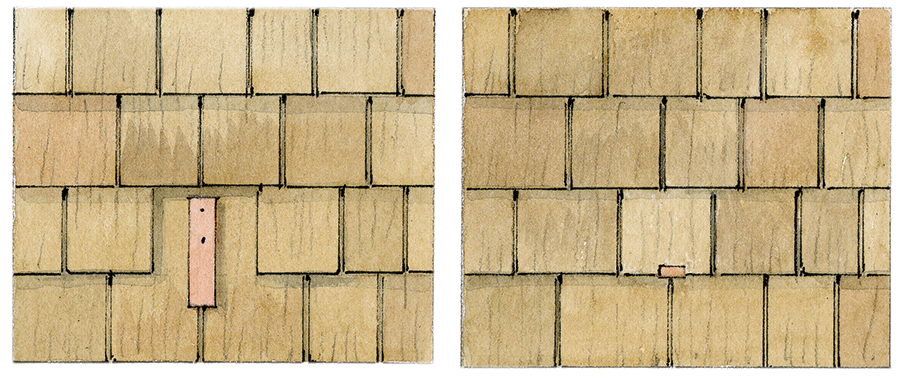

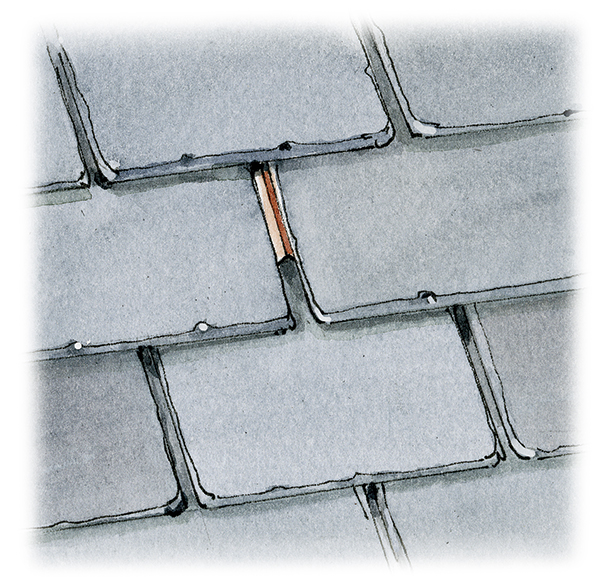

Left: Nail a 1″ strip of 20-ounce copper in the area of the missing shingle. Use copper roofing nails. Right: Insert the new shingle and bend the tab end up. Trim off any excess so sliding ice and snow won’t loosen the tab.

How to Repair Slate Shingles

Although slate is durable, a few slates may break from mechanical shock (a falling branch, a roofer walking on the roof) or due to freeze/thaw cycles. Slates may also be falling off the roof if the nails are rusting away—as when the original installer used galvanized steel nails instead of copper. If the fasteners are failing, there’s really no good solution short of removing the slates and re-laying them, using copper nails.

Working on the roof is tricky because slates are brittle. Pad the roof with an old blanket, or lay a ladder on the roof to work from. A ridge hook is a simple device that attaches to the top of the ladder and hooks over the ridge—you can buy or rent one. Roofers will have scaffold brackets or other equipment.

A simple copper tab (as with wood shingles) can be used, but ice may bend the tab. The method outlined below is surer.

If a whole area of slates needs replacing (or needs renailing), first remove all the slates. This minimizes the number of babies, since some slates can be nailed in the normal way—this is, with the nail holes covered by subsequent courses. Don’t drive nails so tight that the slate is under pressure: the slate should hang on the nail, unlike wood shingles. You can seal the nail hole with elastic cement, roof sealant, or exterior-grade caulk.

Step By Step Instructions for Repairing Slate Roofing

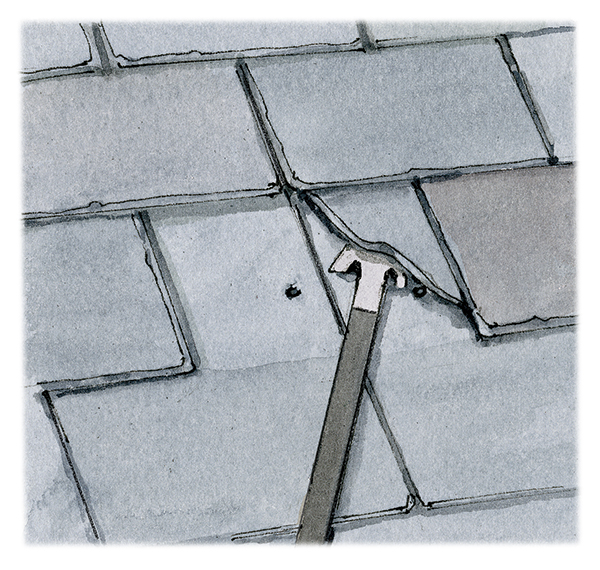

First, remove broken slate, using a slate ripper. Slip the pointed end under the broken slate and hook it over the nail. By hammering downward on the bent end of the tool, you’ll cut the nail shaft. You can pry up the surrounding slates by gently driving nails in sideways. Or use the ripper like a shoehorn.

To replace the broken slate, line up the new slate in its course and be sure pre-punched nail holes (if any) are covered. Mark and punch a hole in the replacement slate, preferably 1″ to 2″ from the next-above slate, but always above double coverage.

You want a hole only in the new slate, not in the one below it. Use a nailset or punch, or drill the hole. A slater’s nail is a heavy-gauge copper wire nail with a large flat head. Its length should be twice the thickness of the slates plus one inch. For standard-thickness slates up to 18″ long, 3d nails are appropriate. Drive the nail; note that the large head was cut to fit between slates in this case. Alternately, you could chip out a bit of each adjoining slate.

Bend a piece of copper slightly convex or concave to make “a baby” (slaters’ slang) to cover the exposed nail hole. Slide it firmly up so the bottom edge is 2″ below the nail. Tap a screwdriver against the baby to push it up, or use the nail trick again.

The baby will stay in place, covering the nail and hole. If concave, it will channel rainwater better.

How to Repair Ceramic Tile Roofing

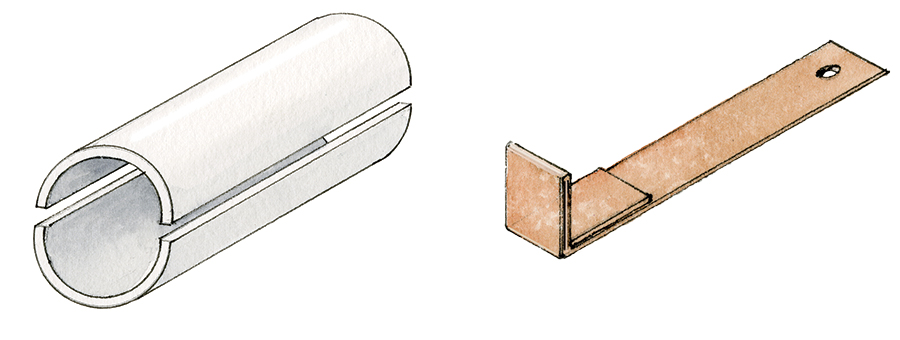

Broken ceramic tiles are fairly easy to replace. As with slate, the hardest part is getting to the trouble spot without breaking more tiles. If any damaged piece of tile remains, remove it by breaking it up with careful hammer blows. Cut the nail with a slate ripper or insert a hacksaw blade under the covering tile. Hold the replacement tile with a copper tab, as shown. Use a double thickness of copper at the end of the tab. The extra stiffness keeps the tab from being undone by the weight of the tile or the force of descending ice and snow. Finding replacement tiles that match can be a problem. You might locate a dealer selling salvaged tile and slate.

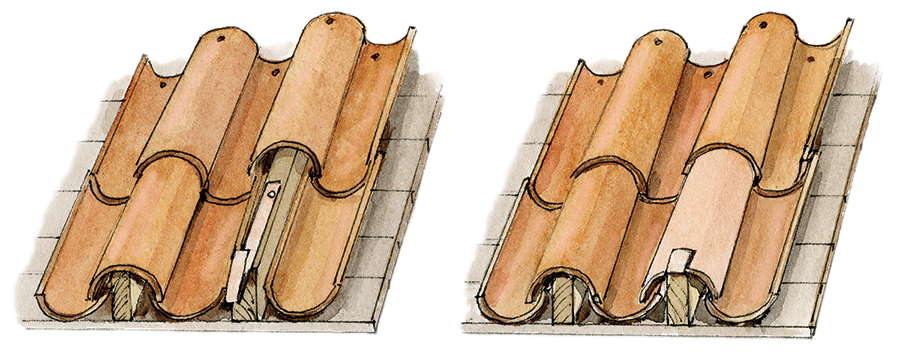

Barrel tile is a semi-cylindrical roofing tile laid in interlocking columns that alternate, with one column having the convex side facing up and the next column having the concave side facing up. If you need just a few pieces of barrel tile, you can fake it with a split piece of PVC drainpipe, painted to blend in with the roof.

Left: After removing the broken tile, fasten the copper tab to a wood nailing strip. Use a copper nail.

Right: Slip a new tile (or PVC stand-in) in place and bend the tab up to secure the tile.

Finding a Leak

If you can see the underside of the roof from the attic, observe it during a rainstorm. You’ll probably be able to see where the water is entering. If the hole is clear through the roofing or flashing, push a wire up through the hole to mark it from the top.

If it’s not possible to push a wire through the roof at the source of the leak, try marking its location by measuring from the nearest convenient reference point, such as a dormer, chimney, skylight, or vent pipe.

Because tracing the precise source of a leak is time-consuming, roofers called in for repairs may resort to using “black goop”: Rather than finding the exact source of the leak, they spread roofing cement over the suspicious area. A dab of roofing cement is acceptable for roll roofing and built-up roofs, where the roofing and patching material are the same.

On a slate, tile, metal, or wood-shingle roof, though, you end up with black pimples. Besides looking terrible, the black patches are very temporary. Roofing cement will dry, crack, and curl; once the patch loosens, water is trapped underneath, hastening deterioration. Also, some patching compounds can chemically damage wood and corrode metal.

Resources

Wood Shingles

Granville Mfg. Co. woodsiding.com

Premium quality shakes & shingles as well as wood siding, since 1857

Slate Roofing

Sheldon Slate sheldonslate.com

NY/VT & Maine roofing slate since 1917