Tim Straley never intended to be a treasure hunter, preserving and reinvigorating a forgotten piece of American history.

Straley always wanted to be an artist, but he always loved architecture and history. He started his career in retail and marketing, but today he’s the founder and CEO of Classic Rock Face Block. His company takes CMUs and recreates rock face blocks using molds designed in-house.

“We all like treasure,” Straley says. “Some people’s treasure is a Star Wars toy, mine is 100-year old concrete molds!”

Straley is always on the lookout for Palmer Machines — 100-year-old devices that ushered in the golden age of rock face block. The more he’s learned about rock face block the more passionate Straley has become. Let’s take a look at the history and modern use of these iconic blocks.

BUILDING AMERICA

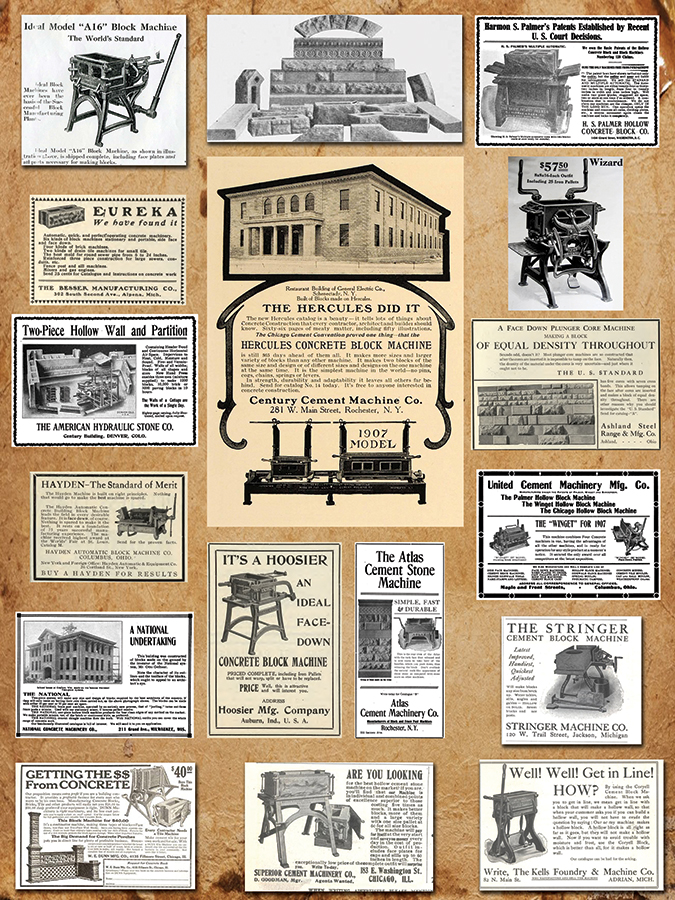

Rock face blocks took off at the turn of the 20th century when an inventor named Harmon S. Palmer patented a small, portable, hollow-block machine named the Palmer Machine.

In the early 1900s, American cities were expanding quickly, and sturdy, inexpensive building materials were in high demand. At that time, the price of brick was increasing and Portland cement was becoming readily available in the United States.

The Palmer Machine allowed construction of rock face blocks on-site, which meant they could be produced inexpensively with nearby materials. This reduced transportation costs and, as a bonus, rock face blocks were larger and easier to assemble than brick.

By around 1901 or 1902, companies like Sears and Roebuck and Ideal Machine — later Besser — were manufacturing and selling their own rusticated concrete Machines. At its height, around 30 to 40 companies were manufacturing the machines. The machines were even shipped around the world to places like Hawaii, Italy, and Egypt!

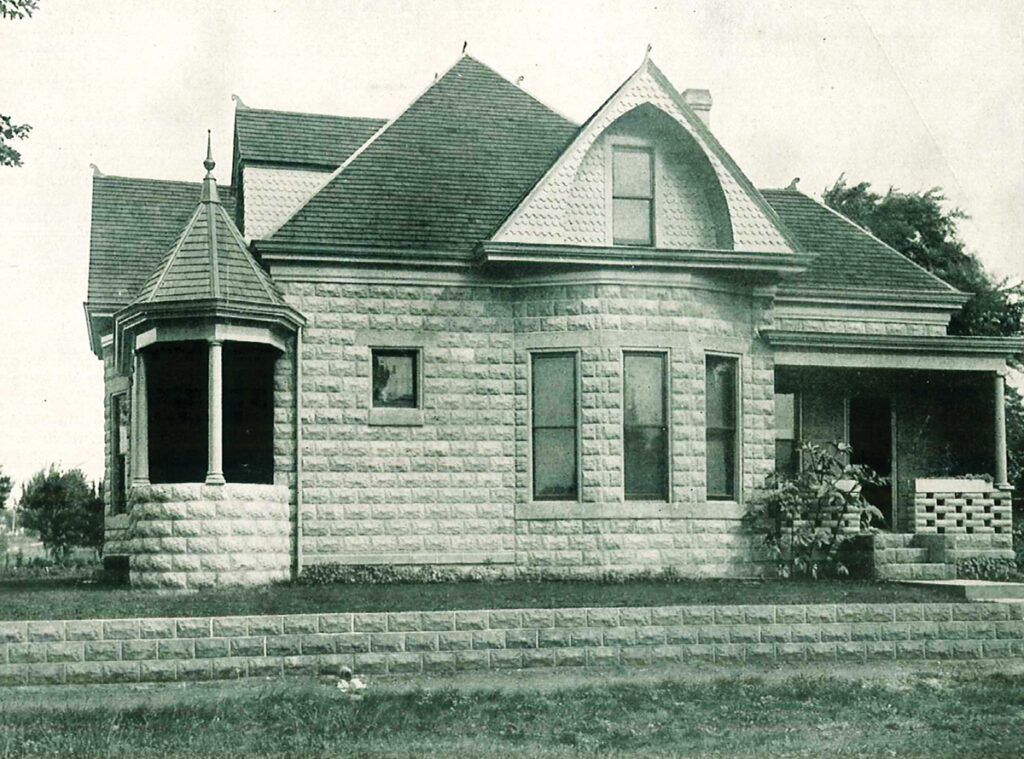

Rock face blocks found themselves used in foundations, porches, garages, and entire buildings and homes.

However, rock face blocks fell off as a popular method of building homes around the 1930s and 1940s. Cinder blocks were patented and transportation became widely available. As a result, masons who used these machines quickly fell by the wayside.

By the time World War II broke out, people around the country were scrapping anything they could for extra metal. The outdated rock face block machines quickly found themselves in the scrap heap.

Still, rock face block had cemented its place in history as small towns and neighborhoods were built across the country.

A MODERN NEED TO PRESERVE HISTORY

Straley founded Classic Rock Face Block in 2006 after stumbling into it on the advice of an acquaintance. At that time, he discovered that the only place in the world selling the blocks was in Australia.

With just one design in hand, Straley got to work. Today, the company has about 50 designs and is expanding their catalog by making castings of blocks from Palmer, Sears and Roebuck and Ideal Machines on old homes.

Classic Rock Face Block has been expanding beyond CMUs into the porch arena with historical accuracy — it now manufactures items like flutes, baluster molds, caps, and capital molds.

Homes with rock face block are often in historic neighborhoods and require exacting standards to be replaced. Because Classic Rock Face Block uses https://sharksinfo.com/ castings of original blocks, historical societies are generally accepting. Anyone who has worked on a historic home can tell you that that’s no simple feat.

“Every conversation I had got me deeper and deeper into it,” Straley says. “When you’re talking to homeowners, or anyone who is fixing a home, the excitement of hearing them say: ‘Oh my gosh, I’ve finally found somebody that does this!’ It just fills me with so much purpose, and I wanna keep doing what I’m doing.”

Classic Rock Face Block doesn’t just restore homes to historical standards, though. The company helps the National Park Service preserve national landmarks.

Straley says he understands infrastructure grows, changes, and evolves, but he hates to see old buildings get knocked down for new ones.

Through its efforts, Classic Rock Face Block and Straley are able to be a living part of history and breathe new life into a nearly forgotten part of American history.