Masonry buildings require relatively little maintenance. Besides occasional cleaning, they’ll need a periodic re-establishment of the mortar joint between the individual stones or bricks; this is called pointing or repointing. Masonry walls must withstand the onslaught of wind, rain, heat, water-vapor migration, and often prolonged freezing temperatures. In a well-built wall, the brick or stone masonry units erode slowly while the mortar is the sacrificial element. When voids and crevices show up between brick or stone masonry units, it’s time to consider repointing. You might do walls sequentially to spread out the cost, since deterioration may occur at a different pace. Many articles have counseled using a mortar softer than the masonry, so that the mortar rather than the brick or stone is sacrificial. Remember the aesthetics, too. Without effort applied toward tooling and color matching, repairs will be painfully obvious.

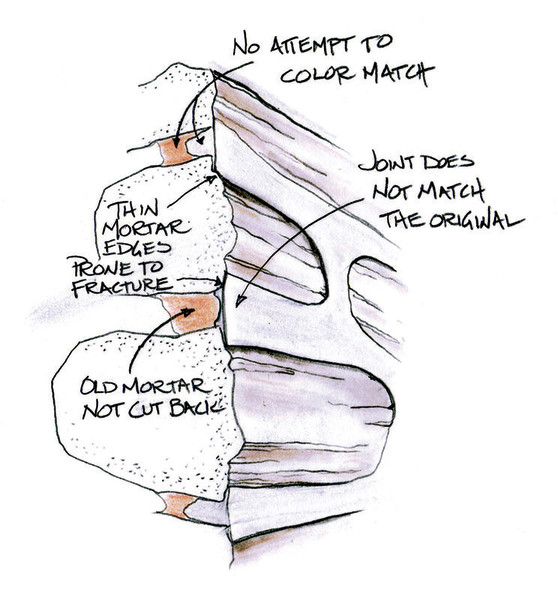

Wrong Way:

Don’t Do a Surface Job

Effective pointing mortar should extend on average ¾” to 1″ into the joint to provide mechanical adhesion; thus, all joints to be repointed should be raked to that depth. Some masons, however, routinely use a latex modified mortar that “sticks” to old mortar. The quick method requires only minimal joint chiseling; the goal is uniform appearance, not longevity. Modified mortar has water-vapor permeability different from that of old mortar and may contribute to masonry failure.

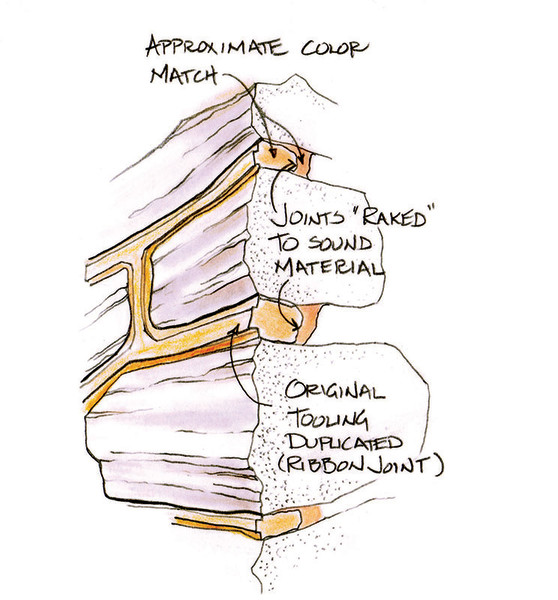

Right Way:

Match Color and Tooling

Unless you are repointing a relatively new house, the bag off the shelf is unlikely to match. In the late 19th century, mortars were commonly colored black, brown, red, and various shades of grey and tan. Sometimes black and white particles were included. Be sure that you or your mason is familiar with the tooling of the original joints, as tooling influences the look and even the longevity of the new mortar. Tape off a 2′ x 2′ area to test the color match and tooling skills.