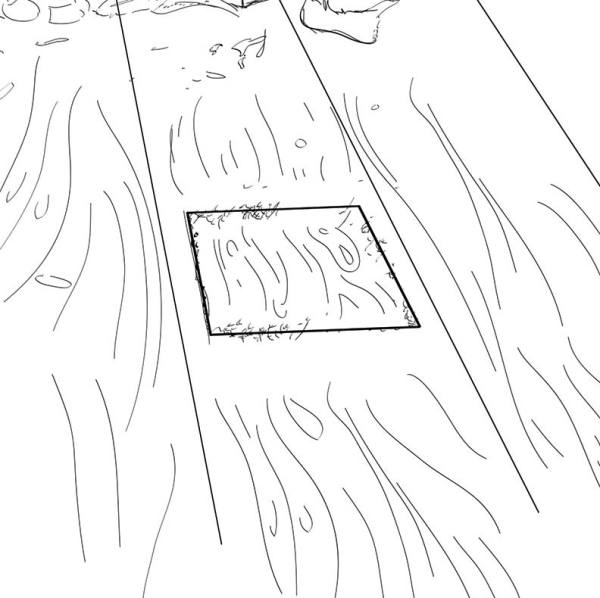

Step 1

Measure an area around the damage.

With a square and a pencil, mark a perimeter approximately ½” around the damaged area. Score along the pencil lines with a utility knife. Using a chisel and a hammer, carefully chip away the wood inside the pencil lines, cutting only to the depth of the damage. Gouges are often just ¼” to 3/8″ deep; splinters are sometimes deeper.

Make a hole for the patch.

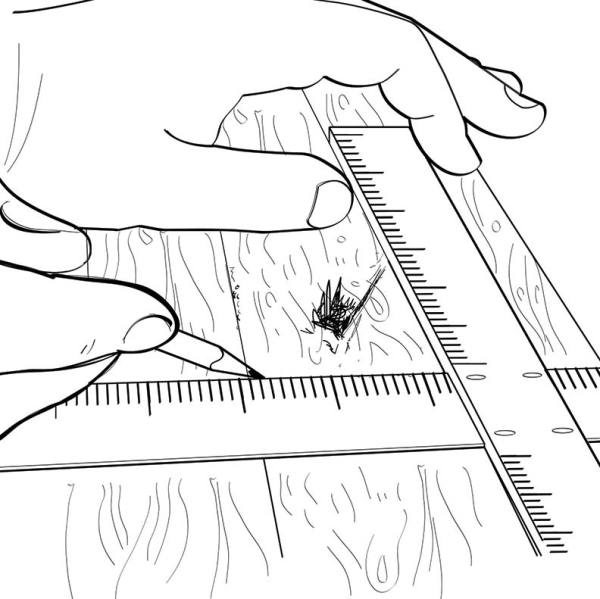

Step 2

Glue the Dutchman patch in place.

Using the same type of wood as your floor and orienting the grain in the same direction as the original, cut a block (the Dutchman patch) to the same width and length as your opening. The Dutchman should be slightly thicker in depth than the repair pocket. Test to see if the Dutchman fits snugly into the opening. If it is too tight, sand the edges of the block or shave them with a utility knife. Too small? Start over with a new one.

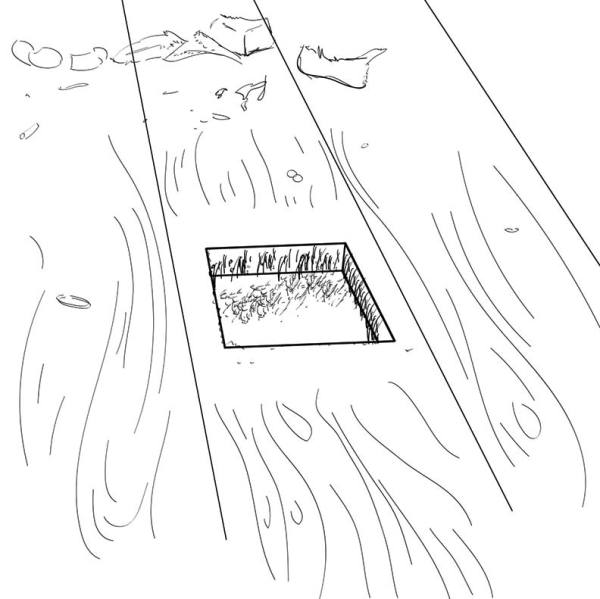

Step 3

Chisel the patch so it’s flush with the surrounding wood.

Apply wood glue in the bottom of the opening, and tap the Dutchman into place with a rubber mallet. Keep the patch in place with a strip of painter’s tape, and let it dry overnight. Use a plane or a chisel to make the Dutchman flush with the floor, then finish it off with sandpaper in successively finer grits so the patch is smooth. Refinish to match your floor.

A look at the finished patch.